Professional contractors know that successful corner bead removal starts with understanding your existing installation and choosing the appropriate removal method.

The right approach prevents costly drywall repairs and saves time. This guide covers proven techniques for removing corner bead while preventing drywall damage during the process.

Essential Tools for Corner Bead Removal

The right tools make corner bead removal significantly easier and reduce the risk of drywall damage.

The primary removal tools you’ll need include:

- A heavy-duty utility knife with fresh blades for clean cuts through joint compound

- A flat pry bar for controlled leverage when pulling the corner bead away from the drywall

- A hammer to precisely position the pry bar when needed

- Professional-grade joint compound knives to protect surrounding drywall

You’ll also need repair supplies, including:

- Setting-type joint compound for immediate repairs

- Paper drywall tape to address torn facing

- Sanding blocks for feathering repair edges

- Spare utility knife blades

- Clean rags for compound cleanup

Having these tools and materials ready prevents project delays and ensures professional results. Before starting, replace any worn tools — dull blades and damaged pry bars increase the risk of drywall damage.

Understanding Corner Bead Types and Their Removal Challenges

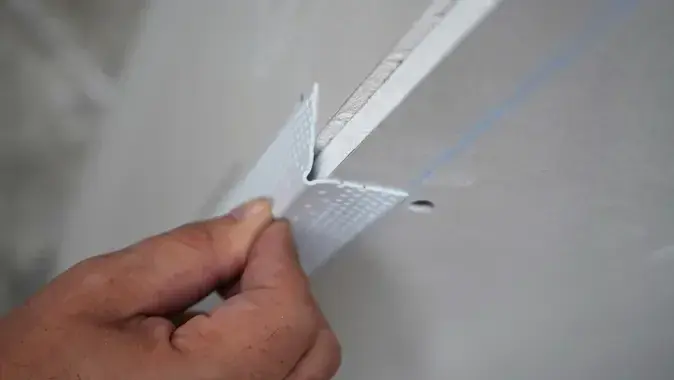

Vinyl corner beads, particularly newer installations using adhesives or mud-set techniques, are often removed more cleanly. The material's flexibility allows it to separate from the drywall with less resistance, reducing the chance of damage during removal.

This makes vinyl the preferred choice not only for initial installation but also for future renovations or repairs. Vinyl corner beads are also far less likely to need to be removed in the first place; most impact can be fixed with a simple mud patch, whereas metal beads will probably need to be ripped off and replaced.

The age of the installation also affects removal difficulty. Older installations often have multiple layers of joint compound built up over decades of repainting and repairs. These layers can make it harder to identify the edge of the corner bead and require more careful scoring before removal begins.

Newer installations typically have cleaner lines and more consistent joint compound application, making removal more straightforward.