For decades, experienced drywall contractors, motivated DIYers and homeowners have used metal corner beads to finish the outside corners of their drywall projects. However, the fact that something has been used for a long time does not necessarily mean it is the best product for the job.

Although a common choice, metal corner beads have some significant issues that prevent them from being the optimal choice for today's top professionals. Rust, durability and installation issues are just a few factors that prevent metal corner beads from being the best option for your drywall project.

Ready to learn more? This article discusses the downsides of using metal corner beads and some superior products that can turn you from drywall zero to drywall hero.

What is a Corner Bead?

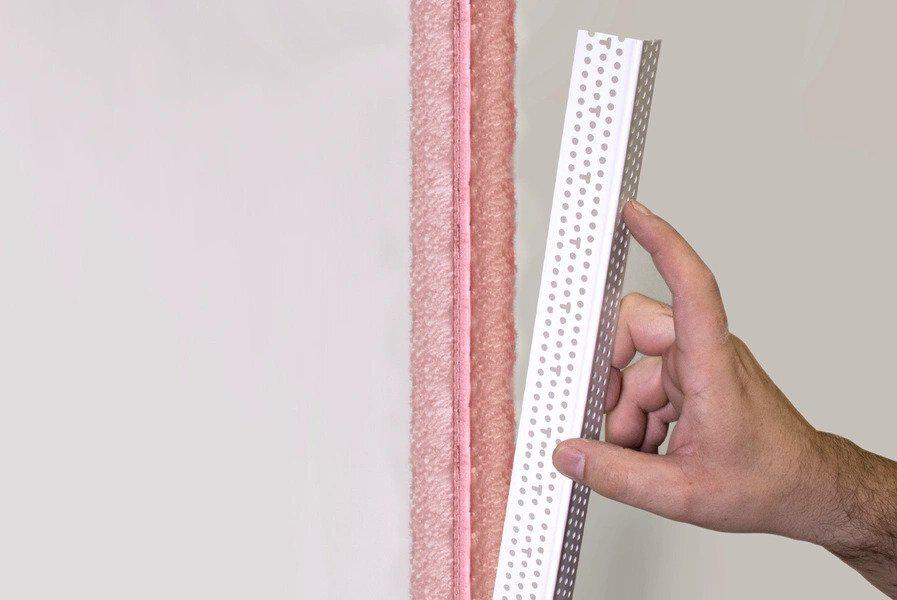

A corner bead is a drywall product used to finish and protect the fragile outside corners of your walls, typically coming in 8- to 12-foot lengths and producing a clean finish for outside corners.

Corner beads also guide your taping knife when applying joint compound to help ensure smooth, flat finish work.

Types of Corner Bead

Traditionally, metal has been used for corner beads. However, a multitude of corner bead types exist today, including vinyl and paper-faced varieties.

Metal Corner Bead

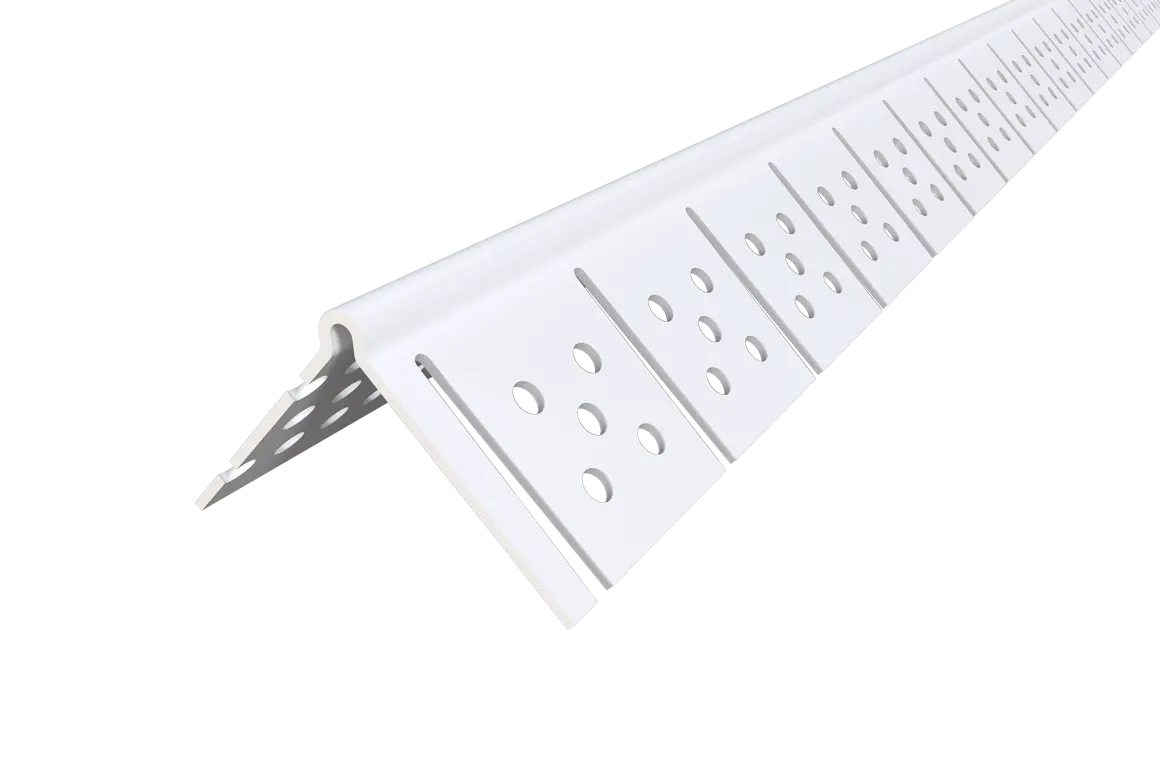

Traditionally, metal is the most common material for corner beads. Metal corner beads are sold in 8- to 12-foot lengths and come in a minimal amount of sizes and profiles.

Paper-Faced Corner Bead

Paper-faced corner beads are typically made of two distinct parts; a metal corner profile and paper attachment flanges. The paper flanges attempt to remedy some of the problems with metal corner bead installation but, unfortunately, often provide their own issues.