It is a problem that has plagued builders and architects since the first modern day skyscraper was built-deflection. Deflection commonly occurs in multistory buildings with concrete floors/decks. Deflection is the degree of movement a structure experiences under a load. This movement causes unsightly cracks in the drywall along the inside corners where the wall meets the ceilings. Over time, deflection causes visual concerns, additional maintenance costs and structural problems.

Instead of accepting deflection as a problem to work around, Trim-Tex decided to tackle it head-on and solve the decades old problem of deflection. The company's commitment to smart manufacturing practices and high quality standards set the stage for the development of a product that would meet the needs of today's multi-story building designs. This product, along with all of our products, are manufactured from a proprietary blend of rigid vinyl material that is comprised of at least 70% recycled material, which keeps 20 million pounds of vinyl out of landfills every year.

Unlike competing products in the industry our products never dent or rust, which reduces jobsite waste and building maintenance costs. Our products also eliminate the chance of mold growth, a problem with paper faced products, making them ideal for maintaining hygienic environments. With a solid foundation of a high quality product and features demanded by builders and architects, the research and design team could focus solely on creating a solution for deflection.

prototype development

With the needs of the problem defined, the R&D team shifted their focus to finding a design that could withstand the movement of deflection while maintaining a clean aesthetic finish that the architects were looking to achieve. Our engineers altered the size, height, and shape of the gasket experimenting with bubble shapes, straight fins, various mounting positions and more. The manufacturing and materials team explored various material blends to reach a final mixture that gave the product the flexibility and rigidity the product needed to move with the building. Overall the team explored over 30 different design and material variations before settling on three designs that moved into field installation performance testing.

the solution

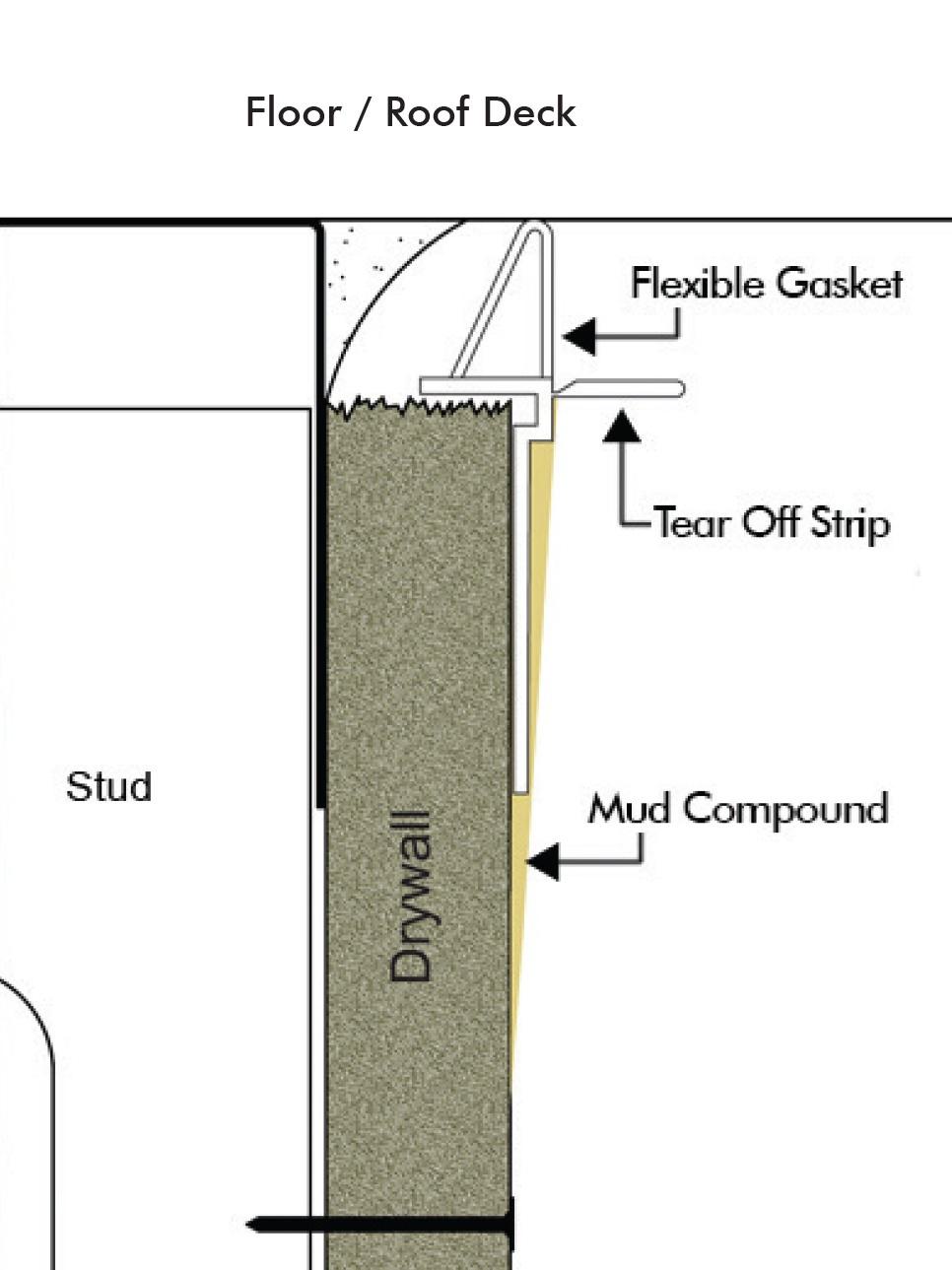

After intense research, testing and development the R&D team created an innovative final product! The product features a co-extruded flexible gasket that is designed to compress under deflection preventing drywall cracks. The product can withstand up to 7/16" of deflection. If the floor system springs back up the gasket is designed to expand back up, keeping it tight against the ceiling. The product also features a tear off strip that is removed after installation leaving a clean straight finished mud edge. Clean, crisp lines are created when the tear off strip is removed. The product protects the inside corner from cracks and pressure due to building deflection, without compromising the design of the building.

This product is a permanent solution for deflection protection.