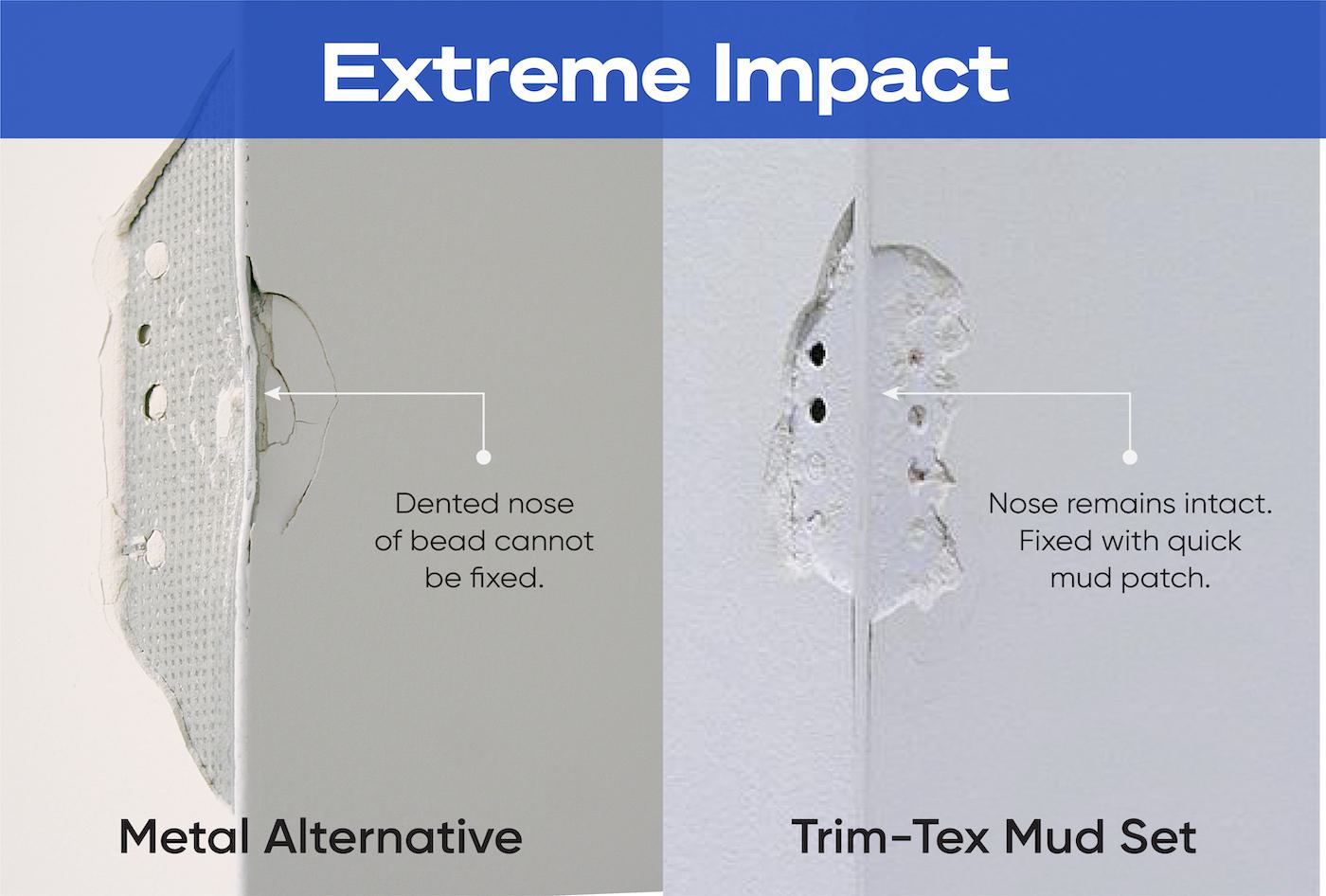

Over the last 50-plus years, Trim-Tex’s vinyl corner beads have been known for just one main installation technique: you hit them with spray adhesive and you staple them. But that’s not the end of our story anymore. These days, there’s a few different vinyl corner bead installation methods to choose from, depending on the solution you’re using and the way you want to work. Are you all about a speedy install, or do you prioritize strong corners above all? Whatever way you finish, we got a solution to match it.

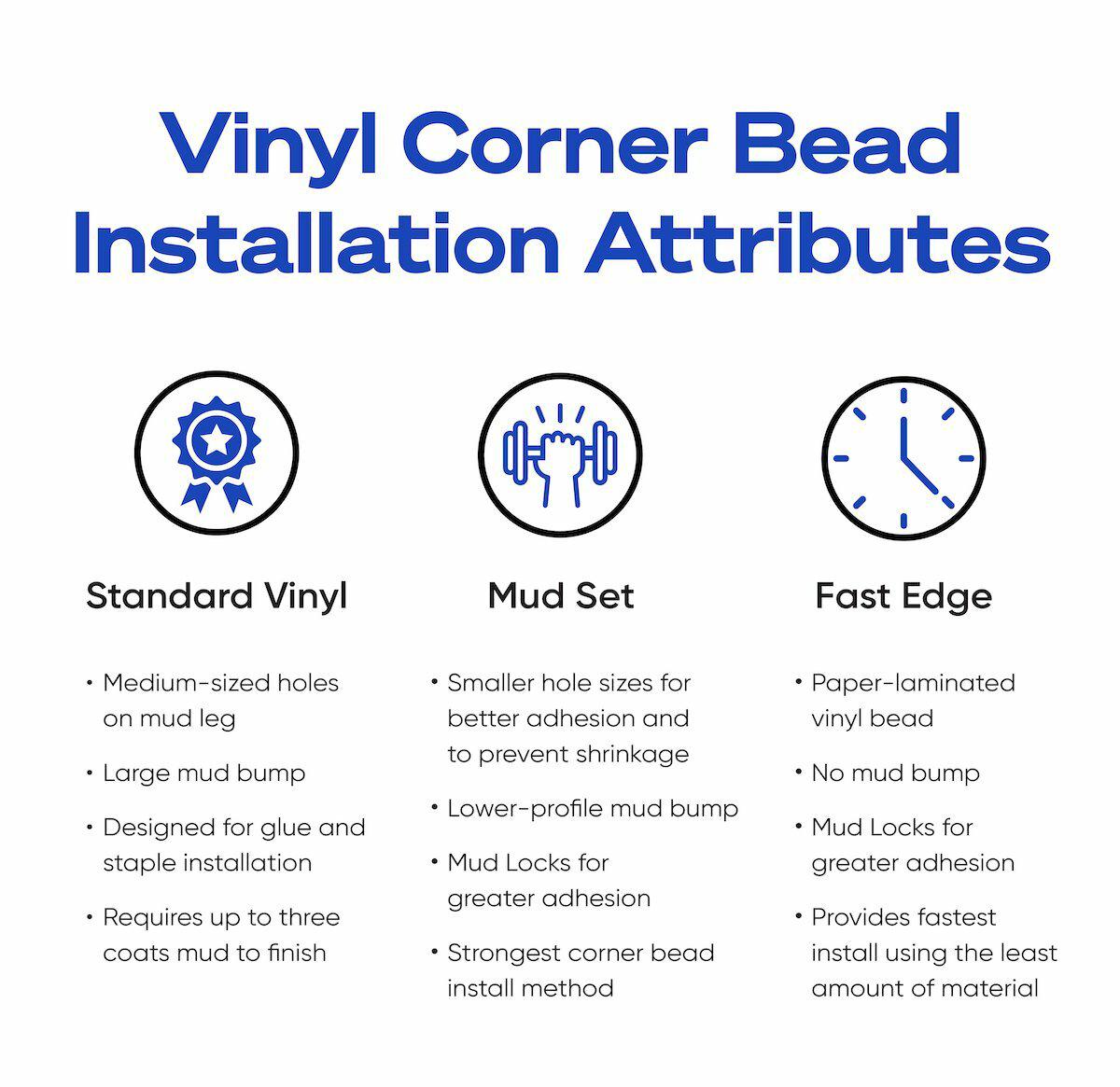

There are three tactics to consider when browsing through our collection of corner beads: spray-and-staple standard vinyl, Mud Set and Fast Edge®. These three techniques are not interchangeable, so be sure to consult product instructions before you begin installation.